During this global crisis, it’s important to recognize the stories of success in the fight against COVID-19. The pandemic has led to growth in the manufacturing sector in many forms. New facilities, changes to production processes, and increased demand for various products are supporting the economy, the supply chain, and the job market. This is the case for a customer of ours in Canada.

Located in Kelowna, British Columbia, Breathe Medical Manufacturing is a manufacturer of disposable face masks to the medical, chemical manufacturing, and food and beverage processing plant industries. Based on current increased demand and future projected volume, Breathe Medical is preparing to open a second manufacturing location. The new 30,000 square foot facility will be located in the Central Okanagan region of British Columbia, and will also be dedicated to producing medical masks.

While designing the new facility, Warren Jones, Partner at Breathe Medical Manufacturing, came across Dorner’s website and contacted Ron Heasman, National Sales Manager for Burlington, Ontario-based Dorner Canada Limited. Due to the timeline and levels of integration required for this project, Heasman recommended Jones work with Shelley Automation, an authorized Dorner distributor with six locations across Canada, as well as Apex Motion Control, a local integrator specializing in full system industrial robotic automation.

Together, Dorner, Shelley Automation, and Apex Motion Control designed a conveyor system to support the planned 12 mask assembly machines.

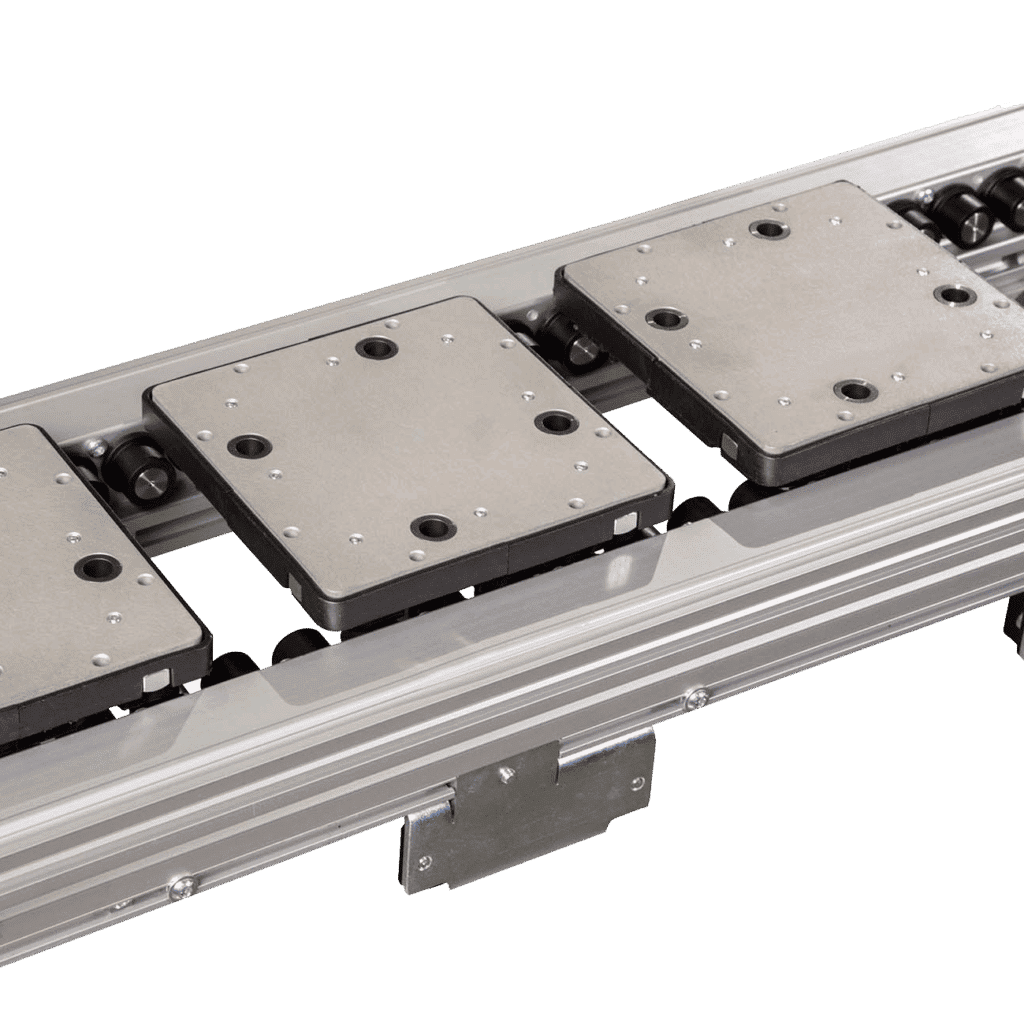

Using Dorner FlexMove Conveyors and custom puck handling, workpiece carriers, Breathe Medical Manufacturing will be able to transport masks from the machines through production for optimal efficiency.

FlexMove conveyors were an ideal solution because of the flexible nature of the conveyor and its ability to integrate with the other machinery. Additionally, Dorner can manufacture and ship the conveyors within the tight timeline to help Breathe Medical Manufacturing start producing as soon as possible.

The full scope of the project includes conveyor assembly and integration, controls, tooling, custom workpiece carriers, interfacing with the purchased equipment: assembly machines, flow wrappers, baggers, palletizers and more.

The project will be implemented in two phases of six machines each. The plan is to hire 30 employees and produce 20 million masks per month to start, with a goal of 80 employees producing up to 40 million masks per month. The first orders are planned to ship in the beginning of June.