- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Pet Food Conveyor Solutions from Dorner Conveyors

Pet Food Conveyor Solutions

Benefits of Dorner Conveyors for the Pet Food Industry

Enhanced Efficiency and Throughput

Improved Product Quality

Superior Sanitation and Hygiene

Reduced Operational Costs

Increased Worker Safety

Scalability and Flexibility

Minimized Downtime

Key Applications of Dorner Conveyors in the Pet Food Industry

- Bulk dry pet food transfers

- Bagging & packaging

- Canning & bottling

- Raw meat & wet food processing

- Ready-to-eat processing & packaging

Ingredient Handling

Sanitation and Washdown

Processing and Manufacturing

Packaging and Distribution

Integration and Automation

Dorner's Sanitary Stainless Steel Conveyor Solutions for the Pet Food Industry

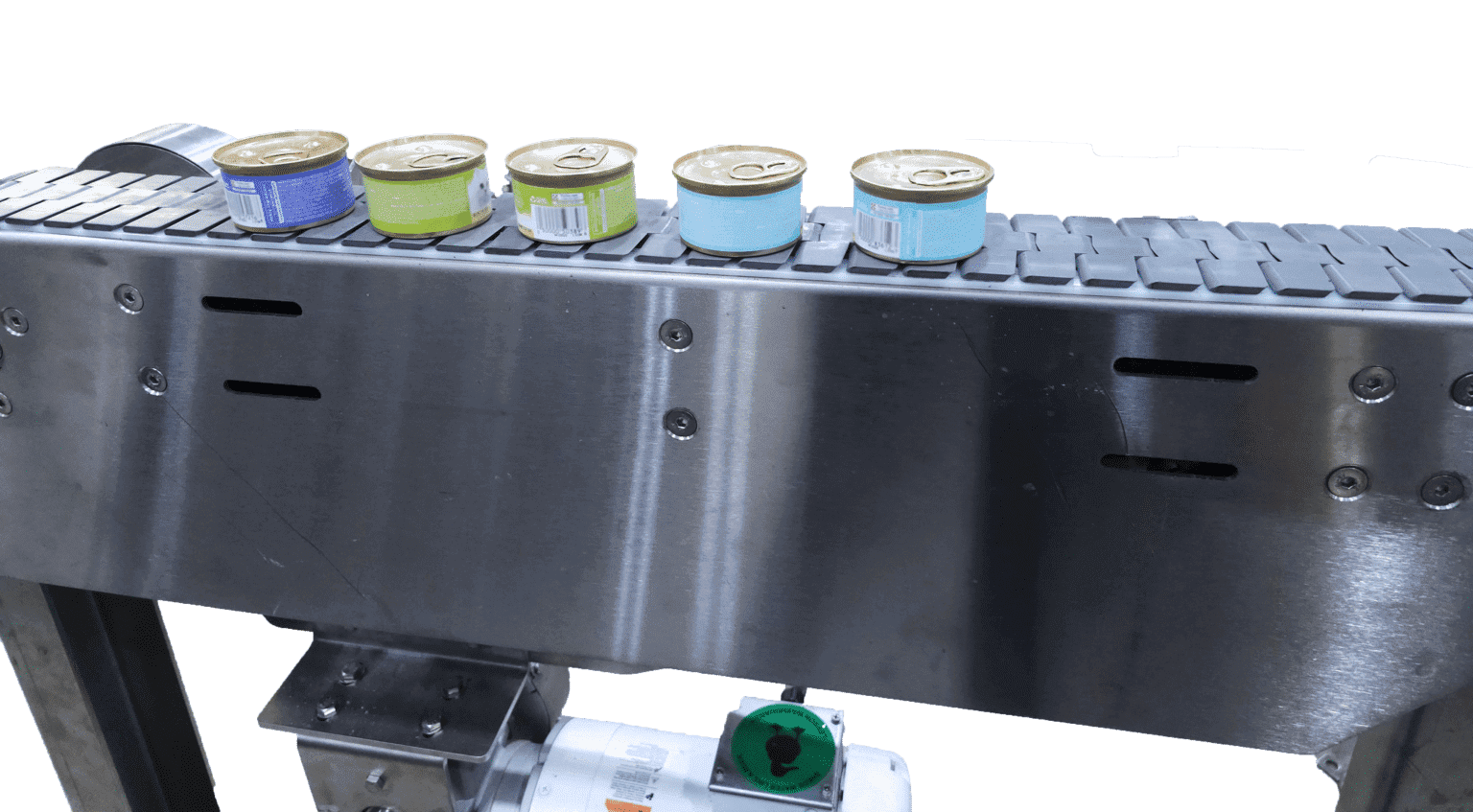

AquaGard Conveyors

AquaGard conveyors are BISCC-approved and designed for dry wipe-down and low-pressure wash applications. These conveyors are perfect for packaged pet foods, machine infeed and outfeed, and canning processes.

AquaPruf Conveyors

Rated for high-pressure and chemical washdowns, these conveyors are designed for the highest level of sanitation. AquaPruf conveyors are the premier choice for handling raw meats and ingredients, ready-to-eat pet foods, and bulk dry food.

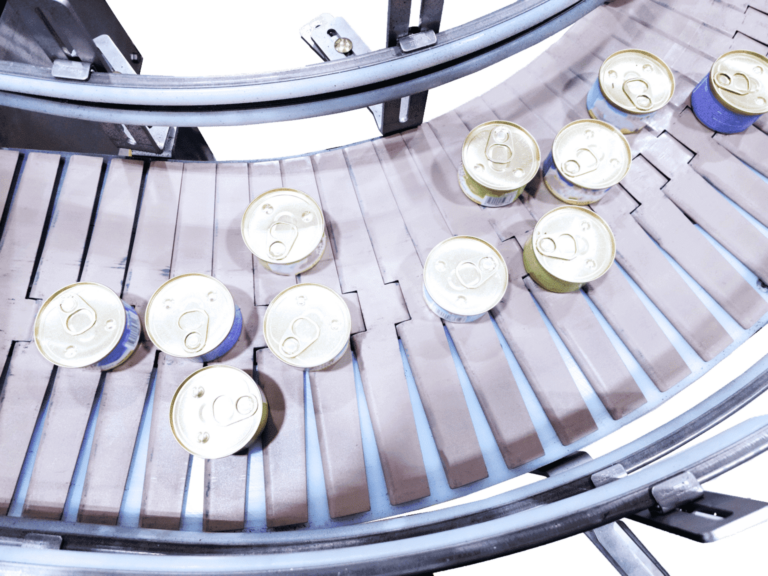

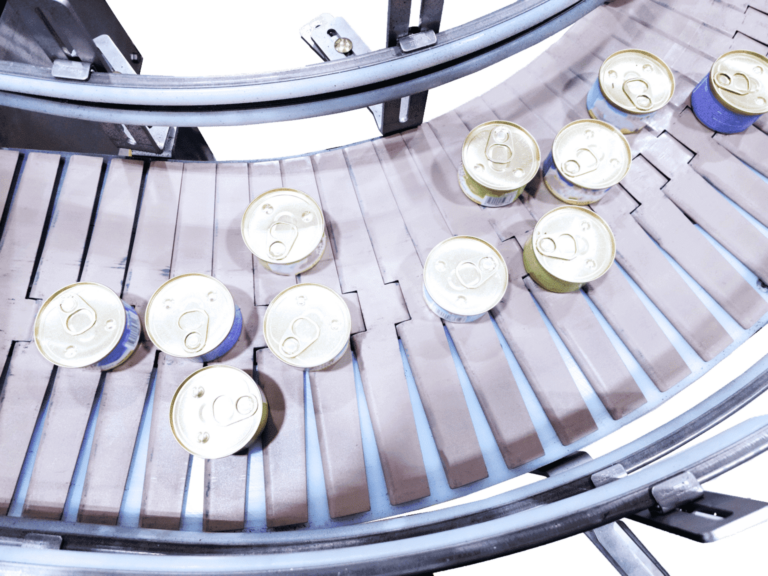

Accumulation Systems from Garvey

Garvey’s accumulation systems are constructed with stainless steel framing and are ideal for packaged food, bottling, canning, and pharmaceutical applications. The wide range of accumulation system sizes and features means each Garvey accumulator is built to your exact needs and specifications.

Sustainability in Pet Food Production with Dorner Conveyors

Sustainable Conveyor Design

- Energy-efficient motors and drives. Dorner's conveyors are equipped with high-efficiency motors and drives that reduce energy consumption and minimize the environmental impact of pet food production.

- Lightweight conveyor construction materials. The use of lightweight, yet durable materials in conveyor construction reduces the overall weight of the system, leading to lower energy requirements for operation.

- Automatic on/off controls to reduce energy consumption. Dorner's conveyors can be equipped with automatic sleep modes or on/off controls that shut down the system when not in use, reducing unnecessary energy consumption.

Durable and Long-lasting Systems

- High-quality materials. Dorner's conveyors are built using premium materials and rigorous construction standards, ensuring a long service life and reducing the need for frequent replacements. This durability minimizes waste and contributes to a more sustainable production process.

- Easy maintenance and service. Dorner's conveyors are designed with maintenance in mind, featuring easy access to critical components, quick-release belts, and modular designs that allow for swift repairs and part replacements. This ease of maintenance helps to extend the system's lifespan, minimizing downtime and reducing the environmental impact associated with complete system replacements.

Reduced Waste in Pet Food Production

- Minimized product damage during handling. Our gentle handling conveyors — like the AquaPruf VBT— offer precise product control features to minimize damage to pet food products during manufacturing. This reduces waste caused by damaged or rejected products, contributing to a more sustainable production process.

- Improved overall production efficiency. By optimizing production processes and reducing downtime, our conveyors help pet food manufacturers improve their overall efficiency. This leads to reduced energy consumption, minimized waste, and a smaller environmental footprint.

How Dorner Is Streamlining Pet Food Production

Operational Excellence

Lean Manufacturing Principles

A Trusted Partner

Customized Solutions for Every Stage

Enhancing Your Pet Food Production with Dorner's Comprehensive Services

Installation Services

Training Services

Exceptional Aftermarket Support

- Thorough system inspections

- Belt tracking and tension adjustments

- Removal of debris and buildup

- Lubrication of critical components

Pet Food Conveyors from Dorner: Custom-Engineered for Diverse Product Handling & Peak Efficiency

Our conveyors are found in fast-paced production lines around the world. When your assembly line is running smoothly and performing efficiently, your company can move faster and smarter. To find out more about Dorner’s professional automation services, call us today at 1-800-397-8664.

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy