Two friends with a dream really can make a difference.

Founded in 1992, Fairytale Brownies grew from two childhood friends, a family recipe, and a home kitchen to a 130-employee-strong enterprise. With a surge in growth in recent years, Fairytale Brownies realized they were outgrowing their current packaging system, and it would soon not be able to keep up. With their contracting agency, John Glenn & Associates, they reached out to Dorner for a new packaging system to help speed up their process.

The Problem

Previously, Fairytale Brownies was using a conveyor to carry product from their wrapping machine through a metal detector and depositing them on a rotary accumulation table where they would be counted and boxed by hand. However, as volume and demand for their products grew, this system was becoming too slow for them to keep up. Manually counting products while boxing was also increasing the risk of errors and miscounting.

Solution

Fairytale Brownies needed an upgraded system that would work with their current wrapping setup, automate some of their packaging processes, and increase their speed. The Engineering Solutions Team at Dorner designed a unique conveyor for Fairytale Brownies that was compatible with their metal detector requirements and added speed and efficiency to their process.

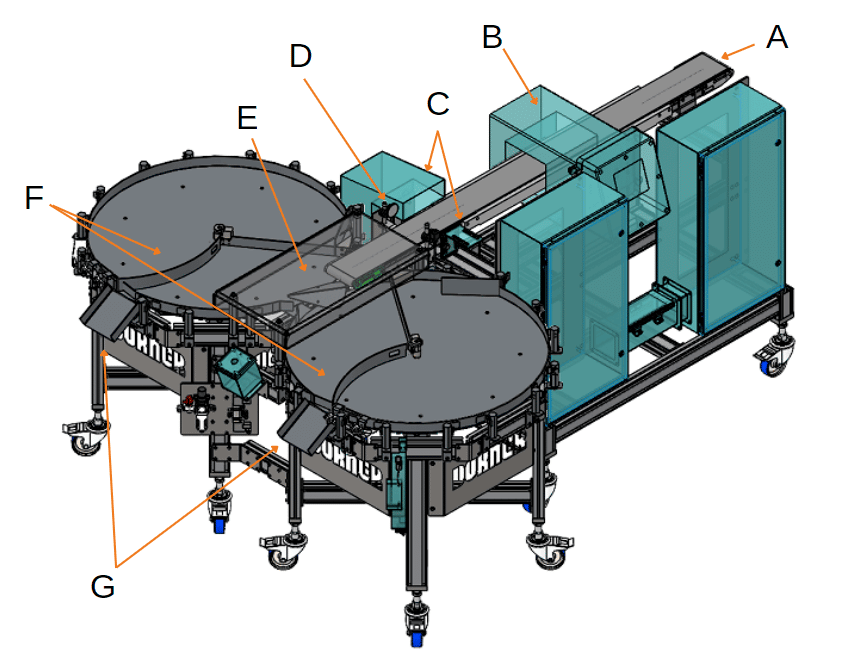

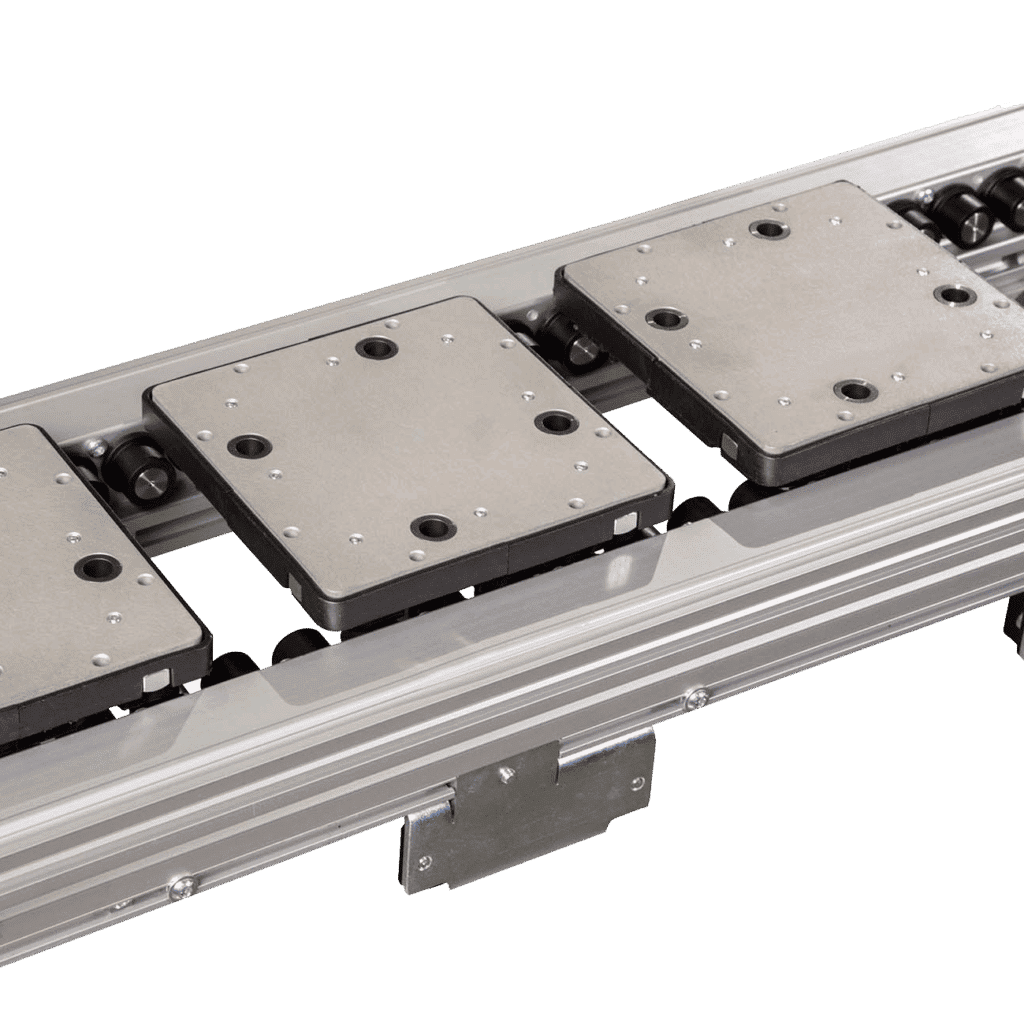

The sweets enter from their product wrapper line, onto a 2200 conveyor (A) which has a special plastic bedplate so the frame will not register in the metal detector. Wrapped products passes

through the metal detector (B), and if metal is detected, it sends a signal to a solenoid valve to activate which sends air through an air nozzle and blows the product off of the conveyor into a reject bin (C).

If no metal is detected, the product passes the air nozzle and goes past a photo-eye sensor (D), which sends a signal to the control panel to increment the count for the product. This is used to keep track of how many brownies have gone through to get packed into a box. Operators can choose the number of products for each counted batch, and once that number is met, the diverter (E) Fairytale Brownies changes position and starts filling up the other rotary table until the next count is met.

For the smallest product (the Magic Morsels), a diverting arm (F) was added that can be set to send product straight to a chute (G) and into a box or bin. No manual removal by an operator needed! The divert arm can also be removed when they are running bigger brownies or cookies so the product continue to go around until it is packed.

The conveyor and tables are on casters, allowing them to be easily moved as needed. There is also a latch to separate the conveyor and two tables so they can move independently of each other.

Implementation Challenges

The challenge in designing a system for Fairytale Brownies came with the need to handle different sized products at high speeds with the same system. The diverter between the two tables was thoroughly tested by Dorner Engineers at varying speeds to ensure it’s accuracy while quickly sending the correct number of products to each table.

Results

With this new system, Fairytale Brownies will be able to keep up with growth and handle increased numbers of products at a faster rate, meeting the demands of their customers. Click here to see Dorner’s solution in action at the Fairytale Brownies facility.

To learn more about how Dorner can help your packaging production process, contact us at info@dorner.com or (800) 397-8664.