Miniature Conveyors

Features of Mini Conveyors

Dorner’s mini conveyors are designed with different sizes, speeds and other features in mind. The following information serves as a snapshot of some common features yet reveals a range of specifications to help give customers a vision for how mini conveyors might work in their businesses.

- Belt widths: 1.75 inches (44 millimeters) to 24 inches (610 millimeters).

- Conveyor lengths: 10.63 inches (270 millimeters) to 98 feet (30,000 millimeters).

-

- Load capacities: up to 150 pounds (68 kilograms).

- Belt speeds: 10 feet per minute (3 meters per minute) to 400 feet per minute (122 meters per minute).

Mini Conveyors Offered by Dorner

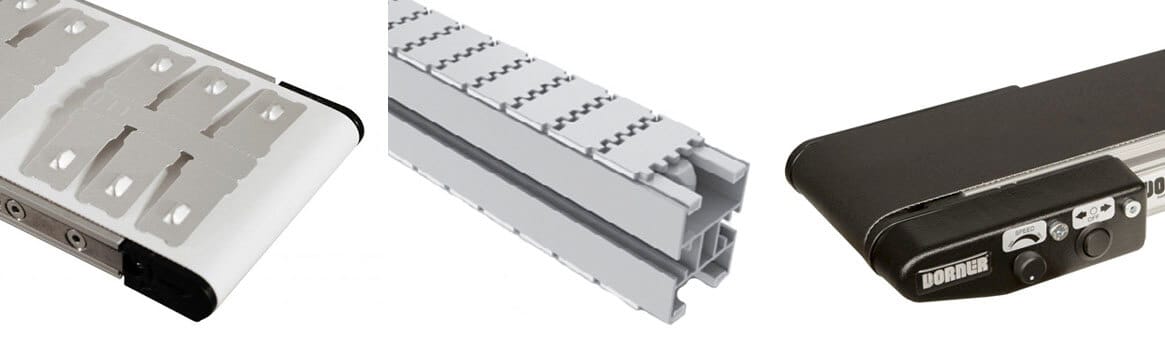

Dorner offers a range of miniature conveyors, from our 1100 Series Conveyor and select 2200 Series Conveyors to our FK 45 mm Aluminum Conveyor.

Let’s examine key characteristics about each of these mini belt conveyors.

1100 Belt Conveyors

Dorner’s 1100 Series Conveyor has earned a reputation for being the industry’s smallest-profile conveyor. This mini belt conveyor is built for small and/or lightweight product movement and is favored for use in the life sciences, medical and pharmaceutical industries.

Our 1100 Series Conveyors are designed with a fabric belt and low-profile height. This minimal height is beneficial in facilities where space is limited by freeing up space ordinarily taken up by machines and/or employees. The 1100 Miniature Belt Conveyor’s small roller diameter enables smooth transfers of small parts.

2200 Belted Conveyors

With a rigid and robust single-piece frame, Dorner’s 2200 Series Belted Conveyors are suited for handling small to medium-size parts. These mini conveyors are generally used for:

- Automated and manual assembly

- Inclines and declines

- Industrial applications

- Packaging

- Part accumulation, infeed and outfeed

- Precision part movement

- Small-part handling, positioning and transfers

Our 2200 Series Belted Conveyors come with the most-compact drive in the conveyor industry. This slim drive saves space and decreases integration time as well as raises the bar on efficiency and productivity. A Universal T-Slot can make attaching accessories and guiding a fast and simple process. Additionally, a nose bar, an optional feature, can help product transfer reach up to 200 feet per minute.

2200 Modular Belt Conveyors

Another low-profile miniature conveyor, Dorner’s 2200 Modular Belt Conveyors are designed for applications in the assembling, general manufacturing, metalworking and packaging industries. Common applications for this mini conveyor include part accumulation, small-part transfers and small- to medium-part handling. Featuring an open frame design along with a plastic chain, Dorner’s 2200 Modular Belt Conveyors are suited for air cooling as well as water and chemical drainage.

These mini conveyor belt systems’ compact profile enables it to be used in space-cramped facilities and placed underneath machinery. Our 2200 Modular Belt Conveyors can be operated at speeds as fast as 250 feet per minute. With Dorner’s optional nose bar, your team will be able to convey product at up to 175 feet per minute.

FlexMove FK 45 mm

Dorner’s FlexMove Conveyors include a miniature conveyor. Our FK 45 mm Aluminum Conveyor model features a compact and clean design and is built to move small items, from perfume bottles to pharmaceutical bottles, quickly. This mini conveyor belt utilizes a plastic chain that allows for horizontal and vertical change of direction. In addition to the standard types, several special purpose chains are available. The FK 45 mm Aluminum Conveyor is used in the life sciences, medical, packaging and processing industries.

Mini Conveyor Applications For Specific Industries

Mini conveyors might feature shorter belt widths and conveyor lengths compared with even small conveyors let alone standard-size conveyors, but they are relied on and valued just as much for their ability to handle lightweight product movement swiftly and efficiently.

Lightweight Product Movement

Businesses creating lightweight products such as perfume bottles, dental floss, eyesight glasses and more require ultra-compact mini belt conveyor systems manufactured and customized by Dorner.

Life Sciences

In the life sciences industry, mini conveyor belts are ideal for moving surgical supplies, respiratory masks, specialty gloves and many other kinds of small and lightweight parts and products.

Medical

Medical companies producing small medical parts and products, from syringes to stents, need appropriately sized solutions to transport items. Dorner’s mini belt conveyors fulfill their needs, offering a range of sizes and customization options to ensure their machine matches their expectations.

Pharmaceutical

Pharmaceutical companies turn to Dorner’s mini conveyors to transport pills, pill trays and bottles as well as assist with package labeling. Our 1100 Miniature Belt Conveyor is a favored choice for pharmaceutical businesses. Our 1100 Miniature Belt Conveyor are favored choices for pharmaceutical businesses.

Mini Conveyors Versus Small Conveyors

One person’s small conveyor might be called a mini conveyor by someone else. Mini conveyors and small conveyors aren’t classified by pure and clean specification differences but instead are relative, especially with regard to the size of a business’ facility. Thus, the terms miniature conveyors and small conveyors are often used interchangeably. The following chart offers some key specification differences among these mini conveyors in a snapshot.

| 1100 Miniature Belt Conveyor | 2200 Belted Conveyor | 2200 Modular Belt Conveyor | FK 45 mm Aluminum Conveyor | |

|---|---|---|---|---|

| Belt widths | 1.75″ (44 mm), 3.75″ (95 mm), 6″ (152 mm), 8″ (203 mm), & 10″ (254 mm) |

1.75″ (44 mm) to 24″ (610 mm) | 3″ (76 mm) – 24″ (610 mm | 45 mm |

| Maximum conveyor lengths | 10.63″ (270 mm) to 72″(1829 mm) in 1/8″ (3 mm) increments | 1.5′ (457 mm) to 24′ (7,315 mm) | 18″ (457 mm) – 30′ (9,144 mm) | 30 m |

| Load capacity | Up to 15 lbs (6.8 kg) | Up to 120 lbs (54 kg) | Up to 150 lbs (68 kg) | Up to 10 kg |

| Maximum belt speeds | 80 ft/min (21 m/min) | 400 ft/min (122 m/min) | 250 ft/min (76 m/min) | 3 to 50 m/min |

1100 Miniature Belt Conveyor

| Belt widths | 1.75″ (44 mm), 3.75″ (95 mm), 6″ (152 mm), 8″ (203 mm), & 10″ (254 mm) |

| Maximum conveyor lengths | 10.63″ (270 mm) to 72″(1829 mm) in 1/8″ (3 mm) increments |

| Load capacity | Up to 15 lbs (6.8 kg) |

| Maximum belt speeds | 80 ft/min (21 m/min) |

2200 Belted Conveyor

| Belt widths | 1.75″ (44 mm) to 24″ (610 mm) |

| Maximum conveyor lengths | 1.5′ (457 mm) to 24′ (7,315 mm) |

| Load capacity | Up to 120 lbs (54 kg) |

| Maximum belt speeds | 400 ft/min (122 m/min) |

2200 Modular Belt Conveyor

| Belt widths | 3″ (76 mm) – 24″ (610 mm |

| Maximum conveyor lengths | 18″ (457 mm) – 30′ (9,144 mm |

| Load capacity | Up to 150 lbs (68 kg) |

| Maximum belt speeds | 250 ft/min (76 m/min) |

FK 45 mm Aluminum Conveyor

| Belt widths | 45 mm |

| Maximum conveyor lengths | 30 m |

| Load capacity | Up to 10 kg |

| Maximum belt speeds | 3 to 50 m/min |

Common Questions About Mini Conveyors

What sizes do you offer?

Dorner’s miniature conveyors come in a wide range of sizes and can be customized for your business’ special needs.

For example, our 1100 Miniature Belt Conveyors come in belt widths of 1¾ inches (44 millimeters), 3¾ inches (95 millimeters), 6 inches (152 millimeters), 8 inches (203 millimeters) and 10 inches (254 millimeters). These mini conveyor belts have lengths as short as 10.63 inches (270 millimeters) to as long as 72 inches (1,829 millimeters) in ⅛-inch (3-millimeter) increments.

How long is your warranty?

Dorner takes pride in engineering and testing all our conveyor designs. Our goal is to ensure our customers experience carefree and world-class performance. Our industry-leading 10-year limited warranty protects the original purchaser against material and workmanship defects under normal use, proper maintenance and cleaning. Dorner will repair or replace defective parts.

What size product will fit on the belt?

Dorner’s mini conveyors are available in belt widths of various sizes from as narrow as 1.75 inches (44 millimeters) to as wide as 24 inches (610 millimeters). Thus, the size of parts and product that belts can accommodate varies significantly.

Moreover, different-sized belt widths can withstand different product weights, with the maximum weight accommodated being 150 pounds (68 kilograms).

Can these small conveyors be combined with other conveyors?

Yes, some of our miniature conveyors can be combined with other conveyors. An example of this is our 2200 Series Conveyors, whose ultracompact drive and Universal T-Slot make it a highly versatile mini conveyor.

If you have questions about whether a specific mini conveyor can be combined with other conveyors, please contact our support team by phone, email or chat.

How portable are these conveyors?

Dorner’s miniature conveyors are highly regarded for their ultralow profiles and simple cleanup demands along with their portability. Some of our mini conveyors—including our 1100 Miniature Belt Conveyors—come as short as just 10.63 inches (270 millimeters). This same conveyor can run up to 72 inches (1,829 millimeters) in length, however.

If it’s slim belt width that’s especially critical, our 1100 Miniature Belt Conveyor can be configured from 1.75 inches (44 millimeters) to 10 inches (254 millimeters). This level of customization makes our mini belt conveyors not only extremely portable but able to meet a variety of needs.

Moreover, Dorner conveyors can be equipped with stands and casters to help make moving our mini belt conveyor systems easy and fast.