Inline Labeling and Printing Conveyors

When it comes to applying labels and printing onto products or packages, our inline labeling and printing conveyors provide a

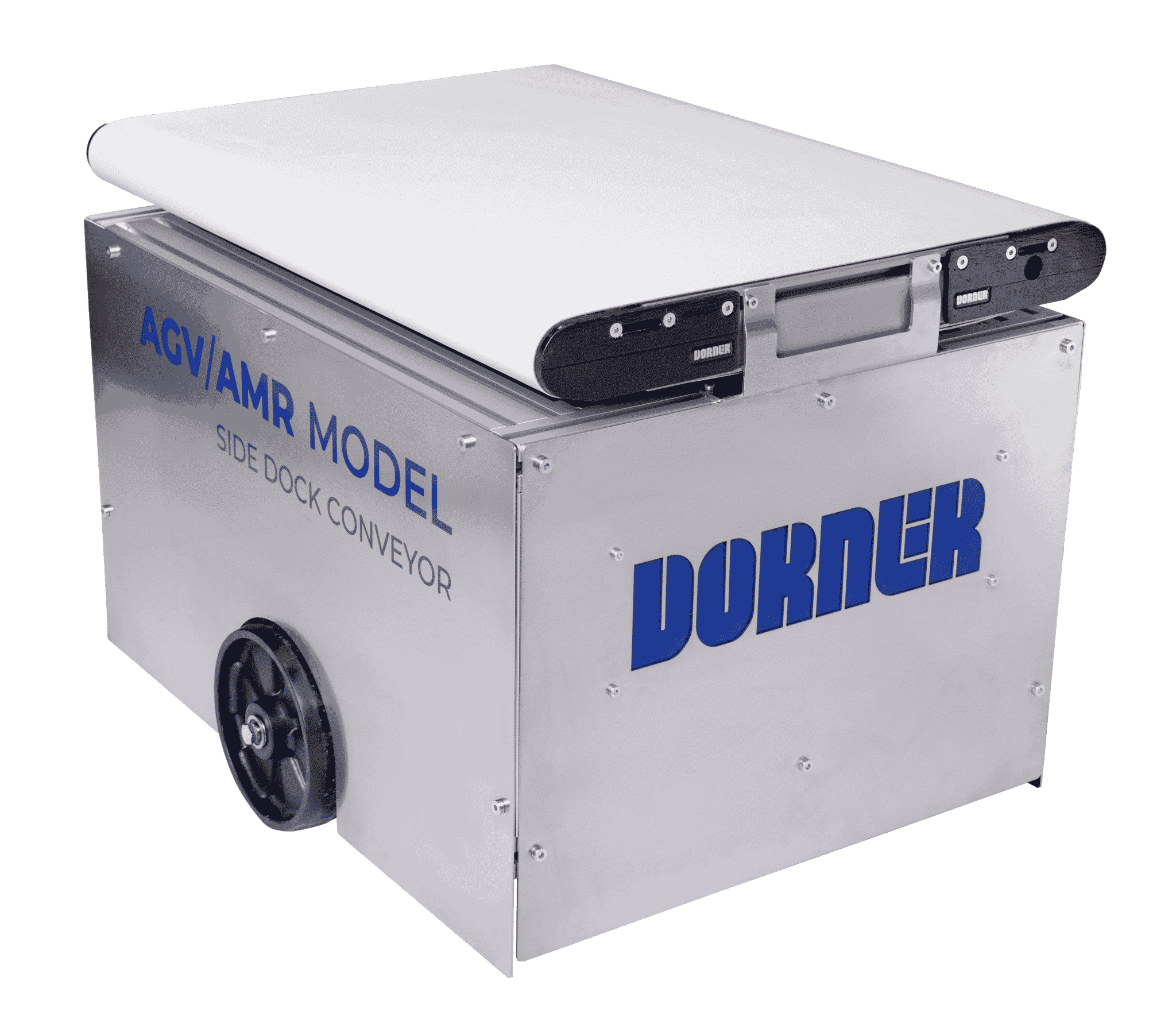

AMRs are the backbone of any automated warehousing or logistics system, and no AMR is complete without an efficient precision conveyor. Dorner has designed the 2700 medium duty conveyor to be just as light weight as our 2200 conveyor systems, but with a higher carrying capacity and wider belting options. A light aluminum frame, internally mounted motor, and precision belt guiding come together into a material handling system that will improve the efficiency and accuracy of AMR systems.

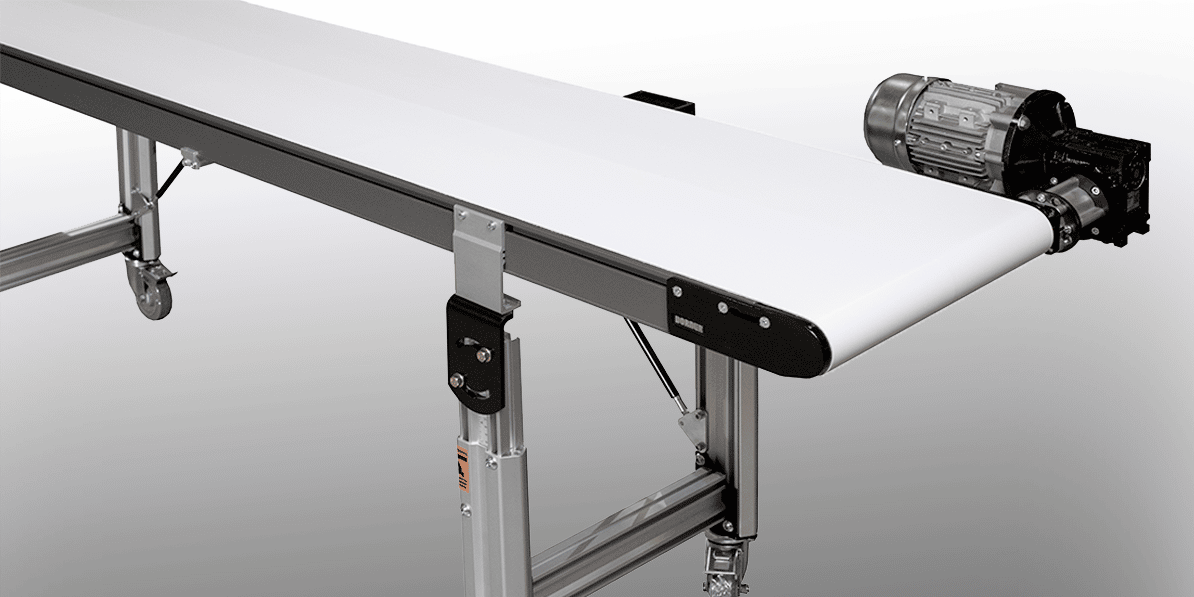

Low profile, high performance, medium duty conveyors. Dorner's 2700 conveyors offer versatility, accuracy, and efficiency to material handling and logistics applications. Whether the 2700 is used as a standstill conveyor for conveyance and sorting, or mounted to an AMR, this conveyor is the ideal solution.

Dorner's iDrive motor is a 24 Volt DC gearmotor that is internally mounted to the conveyor, drastically reducing its footprint and providing the system freedom with a battery powered motor. With no motor taking up spaced on the AMR's profile, robotic vehicles can dock from the side improving both speed and efficiency.

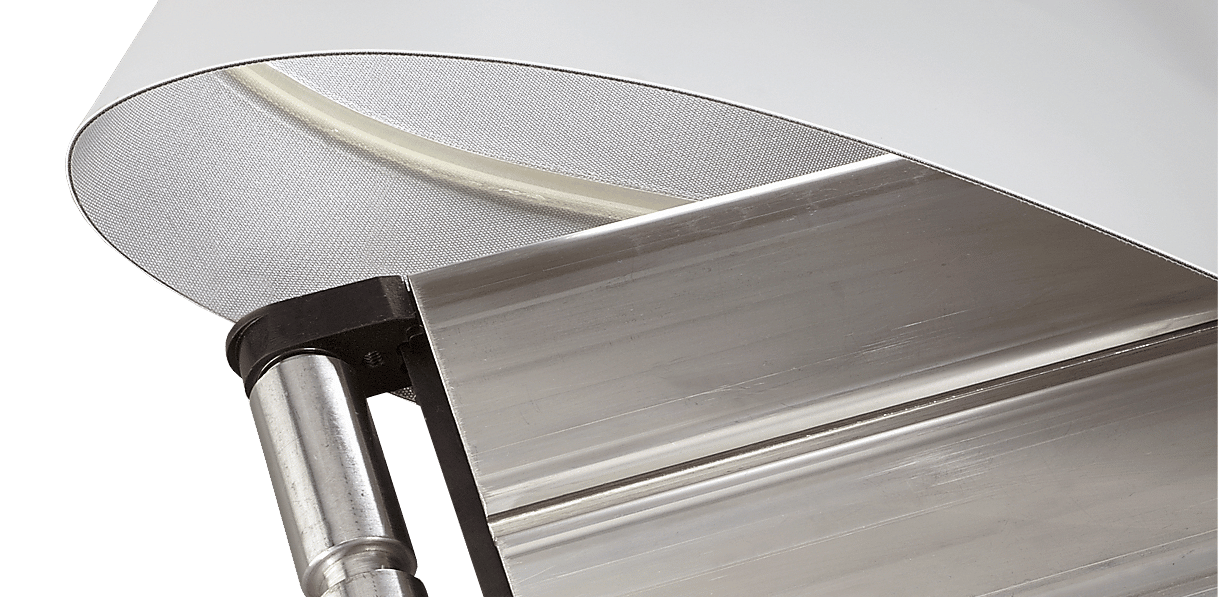

The 2700 Medium Duty Conveyor utilizes our highly accurate and reliable v-guiding to ensure there is no belt sway or slip, even with the belt is wider than it is long. This is especially important for AMR applications, which rely on accuracy to ensure product is precisely placed on the conveyor for transport and sorting.

An AMR Conveyor is designed to be mounted to an autonomous mobile robot. Typically utilized for logistics, warehousing, and material handling applications, AMRs pick up and deliver product from one place to another. AMRs mobility and efficiency require a conveyor that is both lightweight and energy efficient to ensure it has the power needed to move product while being battery powered.

Dorner’s 2700 Medium Duty conveyor is designed to fit the unique needs of AMR applications and can be customized to fit a wide range of mobile robots. With a weight capacity of up to 150 lbs and a lightweight aluminum frame, this conveyor allows AMRs to carry higher payloads without weighing them down. Finally, Dorner’s precision conveyance technology means AMRs mounted with a 2700 conveyor will be able to maintain the highest level of accuracy and repeatability throughout their lifetimes.

When it comes to applying labels and printing onto products or packages, our inline labeling and printing conveyors provide a

Dorner Conveyors offers a variety of automated material handling solutions for companies that want to increase efficiency and productivity. AMR

Gravity roller conveyors are some of the most commonly used types of conveyors in factories and other industrial settings. They

Dorner Conveyors offers a wide range of industrial conveyor systems to help companies move their products and materials more efficiently.

As the world of manufacturing and warehousing becomes increasingly taxed by demand and inflation, it is important to consider what

Modern warehouse automation began with the integration of conveyor belt systems. In the time since those innovations, conveyors have played

What Qualifies As A High Speed Conveyor? The definition of high speed depends largely on the end-user. From an internal

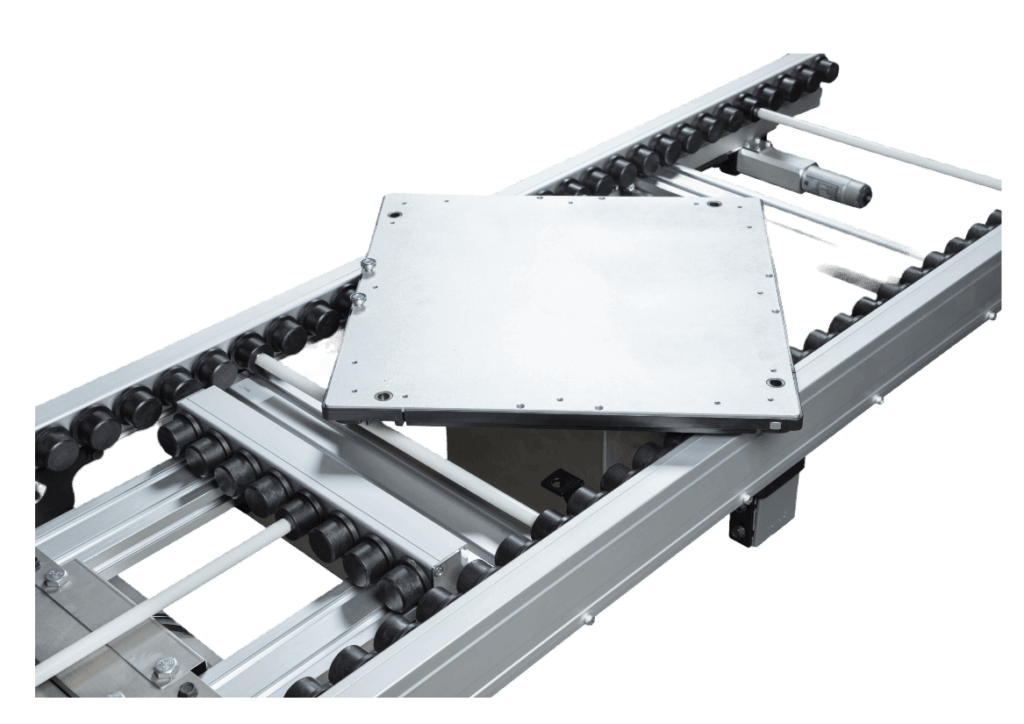

The use of a rotating conveyor in your facility can improve productivity and ensure proper product handling. By reorienting products

LEARN HOW OUR PRODUCTS CAN HELP YOUR BUSINESS

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy